Results

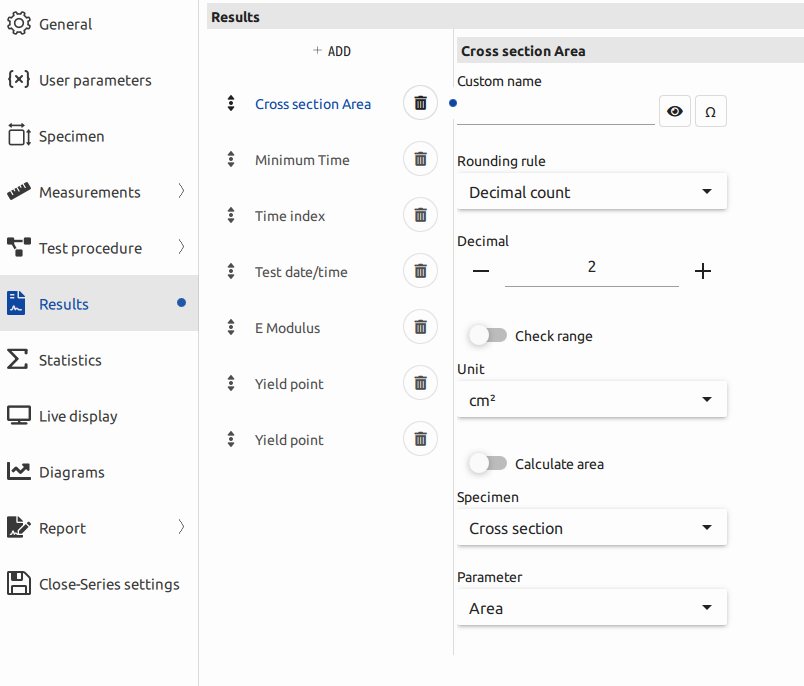

In the "Results" tab, users have the option to add various measurements and metrics to the test results, enhancing the depth and breadth of data analysis. These additional measurements include:

E Modules:

This metric quantifies the Young's Modulus, which represents the material's stiffness or elasticity. It's a fundamental property in material testing, providing insights into a material's deformation behavior under load.

In the "E Modules" measurement setting, users have the option to configure several aspects, which can enhance the precision and presentation of the results:

-

Rounding and Decimal Rules:

Users can define rounding and decimal rules to determine how the E Modules value is displayed in the results. This customization allows for consistent and standardized formatting, aligning with specific reporting requirements.

-

Minimum Valid Values:

The ability to set minimum valid values ensures that only data meeting predefined criteria are considered for E Modules calculations. This helps maintain data quality and prevents outliers or erroneous values from affecting the results.

-

Significance Value Digits:

Users can specify the number of digits of the significance value that will be displayed after the decimal point. This provides control over the precision of the E Modules result, allowing users to present data with the desired level of detail.

-

Modules Secant:

This setting allows users to specify the method for calculating the E Modules, such as secant, which may be preferred for specific applications or materials.

-

Regression:

Users can assign regression settings to customize the calculation method for the E Modules. Regression analysis provides a robust approach to estimating material properties.

-

Automatic Max-Slope:

Users can enable the automatic detection of the maximum slope in the stress-strain curve, which is often used to determine the E Modules.

-

Automatic Max Linear Region Bounds:

This setting allows for the automatic identification of the linear region in the stress-strain curve, which is vital for accurate E Modules calculation.

These configurable settings provide users with the flexibility to tailor the E Modules measurement and calculations to their specific needs, whether it's for research, quality control, or engineering applications.

The ability to arrange settings for maximum force, break point, and yield point, including the option to assign an offset value for the yield point as a percentage, provides users with fine-tuned control over the presentation and calculation of these critical measurements. These settings enhance the flexibility and accuracy of data analysis.

Additionally, the feature that allows users to change the order of results in the "Results" tab by dragging and dropping them is highly intuitive and user-friendly. This capability streamlines the process of organizing and visualizing test data, eliminating the need to delete and re-add measurements in a specific order. It ensures that users can easily structure and display their results as desired, improving the efficiency of data analysis and reporting.

Yield Point:

The yield point is a critical measurement that identifies the stress or force at which a material begins to exhibit plastic deformation. This point is essential for understanding a material's performance under stress.

Energy:

Energy measurements help quantify the energy absorption or dissipation during the test. This data is valuable for assessing a material's resilience and toughness.

Maximum/Minimum:

These measurements record the peak and lowest values of various parameters, such as force, stress, or strain. These extremes are useful for pinpointing critical performance characteristics of the material.

Break Point:

The break point measurement identifies the exact point at which the specimen fails or fractures during the test, providing insights into the material's ultimate strength.

Value Index:

This index provides a summary or weighted measurement that combines multiple parameters or criteria to assess the material's overall performance or quality.

Area Reduction:

Area reduction quantifies the reduction in the cross-sectional area of the specimen after testing, offering insights into the material's deformation behavior.

By adding these measurements to the results, users can conduct more comprehensive analyses and gain a deeper understanding of the material's properties and performance under various conditions. This information is invaluable in fields such as materials science, engineering, and quality control.